Recently, imitation timber is considered to be practical, economical and aesthetic design of the interior in the cottages. This finish is often used in private construction. This material is cheaper than natural wood, but is used in the decoration of any surface.

Content of this article:

Finishing aspects

Imitation of a bar is similar to simple clapboard, that is, individual lamellas are connected using a thorn-groove system. The finished surface has no intermediate patterns, and the lamellas are more massive. Boards are processed on both sides, can be used for exterior and interior decoration.

The popularity of imitation timber is due to a large number of advantages in comparison with alternative types of finishing:

- Ecological purity, naturalness, hypoallergenic.

- Efficiency. With proper calculations of the treated surface and the purchased material, the panels are consumed in a minimum quantity, almost no waste remains.

- Good heat and sound insulation.

- A variety of shades.

- Quick and easy installation (there is a tongue and groove system of connections).

- High resistance to negative factors.

- Excellent ventilation (on the back of the boards there are special grooves). It provides moisture removal, prolongs service life.

But this finish has several drawbacks, including fire hazard, demanding care, expensive components.

It will be interesting to you:REVIEW: Basement siding: Material features. 180+ (Photo) do-it-yourself exterior trim (stone, plastic, wood)

return to menu ↑Material Features

Imitation timber is a flat plate of wood with a thickness of 2 cm. They differ in width (185, 160, 135, 110 mm and less). Along the edges on the plates, chamfers have been removed, giving the surface a decorative effect.

The length of the plates is 2-6 meters. This allows you to purchase items of suitable length, reducing the amount of waste generated.

Imitation timber can be used in the alignment of curved walls. It is only necessary to set the guides evenly and the installation design will be ready. Wood pan suitable for decoration of new objects and reconstruction of old ones.Any wall will look spectacular if you make a wooden trim.

Choosing a shade is difficult. Each product has a unique structure, different colors, so you need to pick wood thoroughly. For example, for recreation and living room it is better to choose light shades, and in mantel zone, the bedroom - dark wood.

It will be interesting to you:REVIEW: Decorative Bark-Blown Plaster: Home Wall Decoration Technology (160+ Photos)

return to menu ↑The choice of material depending on the conditions

When choosing building materials for covering the room, the properties of each tree species should be taken into account.

It is necessary to rely on different aspects:

- Humidity level. In rooms with a higher volume of moisture it is better to use panels of larch, aspen. For objects with high decorative requirements, oak linings are often selected, and cedar and pine panels can be purchased in the living room.

- Purpose of the room. When finishing the house with operation in the warm season, it is reasonable to use inexpensive, beautiful pine panels. For housing with a permanent residence is recommended to use plates of cedar, oak, larch. But at the same time, they take into account that cedar with larch produce a coniferous aroma for a long time, so wood is not suitable for covering bedrooms, children's rooms.

- Illumination degree. This takes into account the shade of the tree. For light rooms, you can choose dark colors of oak, alder. In the rooms facing the north side, fit the bright panels of larch, pine, linden. Cold colors are ideal for painted surfaces, and toning is suitable for beige, cream, yellow shades of wood.

It will be interesting to you:REVIEW: Simple and many-sided Country style in the interior of a country house. 200+ Photos of natural design and simplicity

return to menu ↑Different types of wood for finishing inside

Each type of wood has its own characteristics. Pine has the usual wood texture, yellowish tint. The material is inexpensive, used in the attic of lofts, kitchens, corridors.

Based on the quality of the outer surface, there are several types of fake bar:

- Extra. This is a high grade, different smooth surface of the boards, smooth geometry. It is made from spruce, pine, larch, Arkhangelsk pine.

- Prima (A) Cheaper, can have one knot. It is made from larch, Arkhangelsk pine, spruce.

- Grade AB (B). There may be some small knots. For manufacturing use larch, spruce, pine.

- Economy (BC). An indefinite number of knots is allowed, produced from spruce, pine and larch.

On panels of all grades there should not be through openings, loose rotten knots of resin niches, wane, mechanical damage to external surfaces.

It will be interesting to you:REVIEW: Gypsum Tile for interior decoration: 160+ Photo (under stone, under brick) for bright self-expression

return to menu ↑Interior trimming

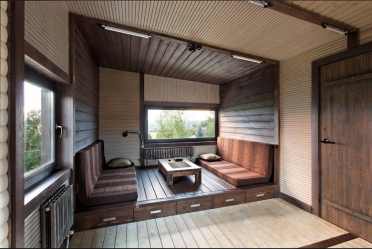

There are many types of finishes, among which it is sometimes difficult to choose. Usually it is used for the ceiling, walls. Two types of plating in the house are used - monolithic and combined.

Wall decoration

Before you decorate the walls with imitation timber, you need to wait for shrinkage (when trimming a new house). At the preliminary stage, the preparation is carried out with antiseptic treatment, vapor barrier, laying crates. After that, the panels are installed.

With the help of this material you can create original, unique interiors in rooms of different functionality. In narrow rooms fit panels up to 100 mm wide, which will visually expand the space.

Ceiling

Sheeting the ceiling surface need after finishing the walls. At the same time, narrower panels are purchased, attached to the crate with a pitch of 50-60 cm, located along the length of the room. Start working from the window.

To calculate the area of the ceiling surface multiply its width by the length. The resulting figure is divided by the area of one beam.. The result is the number of panels required for plating. It is not difficult to count the fasteners: the total number of slats is multiplied by the number of parts needed for fixing a single board.

Before attaching to the surface, the panels should be held for 4-6 days indoors, adapted to the microclimate. Pre-removed from the walls, ceiling pollution, unnecessary parts, cover them with impregnations, antiseptic solutions. Then the vapor barrier and the sheathing are fastened with a construction stapler (self-tapping screws are used at a distance of 70 cm).

When performing a comprehensive ceiling lining with walls, first trim the walls, fix the slats with klyimer. To fix the plastic to the ceiling, use screws or small nails. Connections in the corners are made by the inner and outer corners. At the final stage, grinding, tinting or painting. Processing imitation timber increases the wear resistance of boards.

It will be interesting to you:OVERVIEW: Brick wall in the interior - A spectacular way to transform your home (260+ Photos). The combination in the living room, in the kitchen, in the bedroom

return to menu ↑Exterior paneling

It must be remembered that the imitation of the timber is used for the ventilated facade and there must be a gap between the lining and the insulation layer. It is possible to fasten panels even on objects from a log or a natural bar. This technology is convenient because it allows a long time to maintain the original appearance of the building. Therefore, it is beneficial and rational.

When buying a material should take into account the main nuances:

- Humidity level up to 15% (so as not to cause a skew in the facade during operation).

- The presence of grooves. Longer preserve the original appearance of the panels.

- Width is about 100 mm. Siding will look like a bar. With a smaller width of the panel will look cheap, and wider - sloppy.

- The quality of the castle connection.

- Smoothness, evenness, no damage and defects.

Pre-calculate the material with components, measure the walls, window openings and doors.

Quality panels are not difficult to install. But the work is carried out in strict sequence:

- Prepare a surface, clearing walls of pollution. They can be treated with antiseptic from pathogenic microflora.

- Vertical to the base is lathing, fastened with dowels or screws.

- Quality steam and heat insulation is laid. Insulation attached to the vapor barrier film and it is closed, the glue joints.

- Fix panels with decorative elements.

- The facade is attached with studs or screws.

- Cover with antiseptics, varnishes.

Attach the panel to the bottom up, the grooves are placed in the bottom. This will prevent moisture from entering. The first bar is set with a level, since the levelness of the surface will depend on its proper installation. Fasteners screwed at a 45-degree angle.

To extend the life of the facade, lined with strips, should properly care for the surface. It is necessary to periodically coat them with varnish, check for the presence of rotting, fungus and defects.

With proper laying and care of the coating, imitation of a bar will serve for a long time, not to lose its positive properties and beauty.

It will be interesting to you:REVIEW: PVC panels for walls: 235+ (Photo) for your interior (for kitchen, bathroom, hallway)

return to menu ↑Varnish and paint

The type of protective agent, impregnation and components depends on the conditions of the room. It may be:

- Room in the room with heating. You can use a simulating beam without careful processing and special impregnations. Material can be varnished.

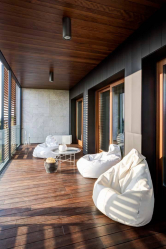

- Unheated room (closed verandacottage room). Need a choice of wood with several layers of antiseptic, linseed oil. This will ensure the resistance of the surface to negative impacts.

- In the bathroom, sauna, bathhousewhere high humidity is typical, changing temperatures requires the use of a galvanized profile, the use of special protective compounds.

When coloring wood cover with structure of a certain shade.

Pre-examine the existing range, taking into account the following aspects:

- Invisible transparent compositions highlight the beauty of wood and retain their original appearance. With the help of such mixtures can be combined shades. These are stain, impregnation, glazes, various varnishes.

- Colored dyes applied to the primer. Paint can be formulated for interior decoration.

Regardless of the paint chosen, the surface must be carefully prepared and primed.

It will be interesting to you: REVIEW: Kitchen wall decoration: 205+ Photo Options (panels, laminate, plaster). How to combine practicality with aesthetics?

return to menu ↑Apply simple paint on wood

Panels treated with a simple solution undergo the usual processing steps. You can apply any paint, including acrylic, alkyd or oil based. The technology includes the following steps:

- Cleaning the front part of the wall paneling, sandpaper processing.

- Details are treated with a soft brush, removing dirt from them, treating with an antiseptic. It is better to use colorless formulations in order not to change the color of the applied paint.

- A primer is applied to the wood.

- The bar is painted using a roller, brush or spray gun.

To better highlight certain areas, you can tint the primer. This will evenly apply the final coating.

Painting is better to postpone if the room is high humidity or very hot.

return to menu ↑Use colorless coatings

Colorless and environmentally friendly liquids have high adhesion. They protect the timber from destruction, emphasize the unique texture. When drying, there is no unpleasant smell and does not require constant air circulation.

Also, a protective film can be created with turpentine, rosin and linseed oil. With the help of organic solutions will be provided protection, emphasizing the natural beauty, the steam barrier against the penetration of moisture into the imitation of the beam.

It will be interesting to you: REVIEW: MDF panels for the kitchen - 250+ (Photo) Finishing options

return to menu ↑Textured color

The advantage of textured dyes is to give the material a special beauty, uniqueness. The texture can be emphasized in different ways:

- Getting relief contour using a metal brush. She is carried out several times along the grain of the wood. As a result, the soft fibers disappear, but the solid ones remain intact. After painting the wood, the crumbs that appear are removed with a soft brush and covered with a layer of glaze. The remains of glaze get wet with a sponge, put a transparent varnish.

- The technique of “bleached” wood is created by a similar finish.. Only with this use white color coating glaze, put it on a colorless varnish, and the residues are soaked with a sponge. As a result, small gaps become white, and embossed particles retain a natural shade.

- Aging under the mechanical influence of the hands, so artificial slight damage appears on the surface.. Facing ground, treated with a chisel to the formation of chips. You can also pierce nails several times, apply other microtrauma to wood.

It will be interesting to you:OVERVIEW: Wood interior: 200+ (Photo) Ready-made natural designs for your comfort

return to menu ↑Some interesting ideas for using false beams

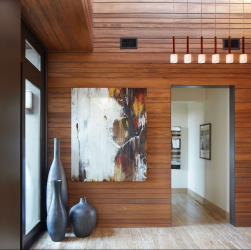

Now wood paneling allows you to create a design room in the style of a bungalow, a chalet for hunters, connoisseurs of wild nature. Such material allows the use of ethnographic styles, which are now particularly popular. Wood trim creates an atmosphere of comfort, comfort, makes the interior restrained and unobtrusive.

The surface of such panels is flat (in comparison with the block house), so they can handle any room while maintaining the usable area.

Imitation of a bar allows to receive an eco-friendly interior with the minimum expenses.

There are several unique solutions for the use of timber:

- The combination of wood with plaster. The facade can be veneered with different finishes. For example, suitable panels with a layer of plaster. It turns out a house with smooth lines, elegant and strict. Its height will increase visually due to the "striped" ornament.

- The combination of stone with a bar. This is a good combination that can be made in equal proportions. Stone ornaments will emphasize the natural finish, the superiority of wooden materials.

- Full wood trim outside. Anyone can have such a home. The layout is suitable for permanent living or outdoor activities. Bar can be trimmed inside and outside in accordance with the exterior and interior.

- Imitation of the walls of the log. At first it seems that the house is made of round logs, but these are only panels. The technology is simple, it allows to preserve the naturalness of the raw materials used, while maintaining the quality of the structure.

The cost of finishing will depend on the price of false panels, on the complexity of the geometry (the simpler it will be, the lower the labor costs).

return to menu ↑VIDEO: Beautiful finishes with imitation timber

Imitation timber

The best options in design